How to maintain digital withstand voltage partial discharge control system?

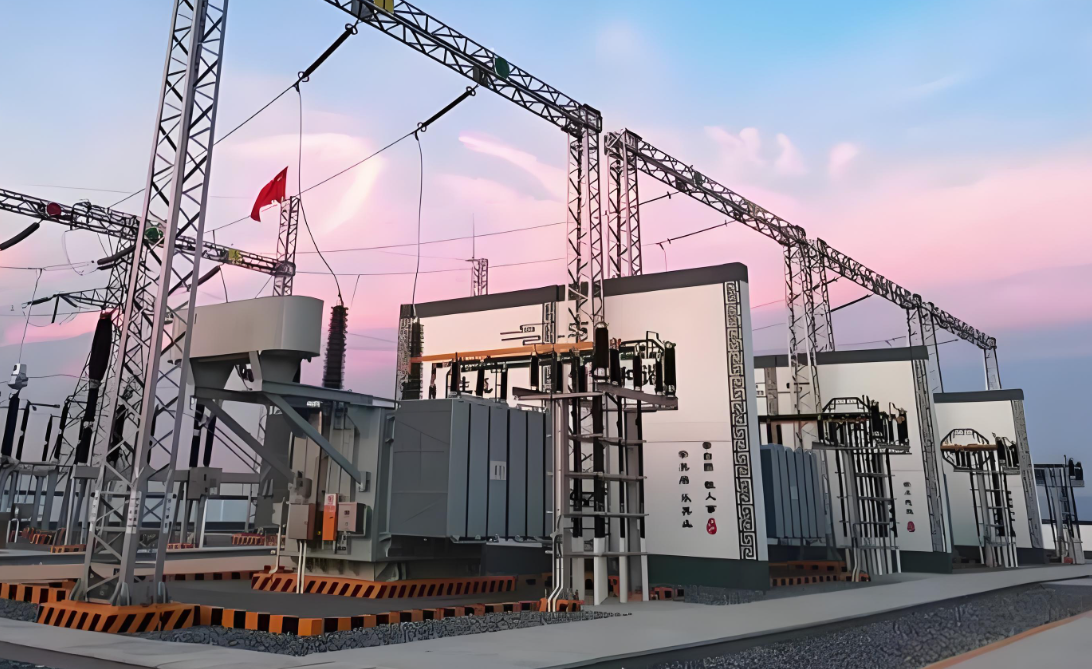

The system is substation equipment for power supply and distribution systems., power transformer manufacturing plants, industrial and mining enterprises, research departments, etc., for testing the insulation strength of various high-voltage electrical equipment, electrical components, and insulating materials under power frequency or DC high voltage. It is an essential piece of equipment in high-voltage testing. It ingeniously combines the no partial discharge test device (transformer control section) with the partial discharge detector, making the testing process more. During use, we also need to regularly maintain it. Here is how to maintain the system.

1. The YXY-D630 Intelligent Insulation Test Comprehensive Control System (Cabinet) of maintenance

Daily maintenance tasks

Visual inspection: Remove dust from the cabinet and check if the control wires inside the cabinet are making good contact.

Panel button check: Inspect the display lights and button operation status on the panel.

Control board check: Check if the display lights on the control board are blinking normally.

Weekly maintenance tasks

Calibrate the pulse generator to correct 50pC to test if the partial discharge signal is properly connected. And it also contains the daily maintenance tasks

Monthly maintenance tasks

Tighten screws inside the cabinet, control board, and terminal blocks. Check the computer operating system and software functionality (manual test functions, automatic test functions, status of various icons while software is running, etc.). Perform power-off cleaning inside the console, and if there are oil-immersed equipment inside, check for oil leakage issues. This includes daily and weekly maintenance tasks.

Annual maintenance tasks:

Calibrate voltage, current, and other parameters of the control cabinet, which should be handled by professional equipment personnel or by the manufacturer.

2. Circuit breaker cabinet maintenance

Daily maintenance tasks

Clear the dust inside the cabinet and check if the control wires inside are making good contact.

Inspect the appearance of the isolation transformer and filter components to ensure they are normal.There are buttons or indicator lights, check their functionality and clean the exterior.

Weekly maintenance tasks

Secure the screws and wiring terminals inside the cabinet, check the voltage, current, and insulation of the transformer and isolation filter, and include daily maintenance tasks.

Monthly maintenance tasks

Inspect the voltage regulator motor, ensuring that the carbon brushes make proper contact with the coils. During operation, check if the carbon brushes are functioning normally and if there is any obvious sparking. Observe the coils for signs of carbonization (black spots), and if black spots are present, they should be promptly sanded down. Ensure all terminal connections are secure and verify that all functions are operating correctly, including daily and weekly maintenance tasks.

Annual maintenance tasks

Annual inspection of switchgear should be carried out by professional equipment personnel or handled by the manufacturer.

3. The test transformer+protective resistor+coupling capacitor containeance

Daily maintenance tasks

Visually inspect the voltage equalizing cap for any deformation or burrs, and check the transformer body for any oil stains.

Visually examine the transformer's appearance and pay attention to any unusual noises during operation.

Weekly maintenance tasks

Secure all terminals. When the temperature exceeds 30 degrees, vent once a month; otherwise, vent every three months. Also, include daily and weekly maintenance tasks.

Secure all terminals. When the temperature exceeds 30 degrees, vent once a month; otherwise, vent every three months. Also, include daily and weekly maintenance tasks.

Annual maintenance tasks

Test the turns ratio, check the insulation of each winding, and measure the DC resistance. This annual inspection should be carried out by professional equipment personnel or handled by the manufacturer.

4. regulator

Daily maintenance task

Check for any unusual noises during operation, inspect the voltage regulator coil for foreign objects, and clean off any dust.

Weekly maintenance task

Secure all terminals, test upper and lower limits, and include daily and weekly maintenance tasks.

Monthly maintenance tasks

Secure all terminals, test upper and lower limits, and include daily and weekly maintenance tasks.

Annual maintenance tasks

Check the wear on the carbon brushes. If they are worn too much, observe the coils for signs of carbonization (black spots). If black spots are present, sand them down promptly. This inspection should be carried out annually by professional equipment personnel or by the manufacturer.

The above content by demiks finishing released, reproduced please specify, demiks is a substation equipment manufacturers, specializing in the production of partial discharge tester, transformer test equipment, circuit breaker test equipment, relay tester, SF6 gas analyser, cable fault tester and other products, such as electric power testing and inspection needs please feel free to contact demiks power science and technology limited company or send an email! to us: contact@demikspower.com

Relay Protection Testing and Commissioning Gu

Relay Protection Testing and Commissioning Gu

how to test microwave transformer

how to test microwave transformer

how to reset circuit breaker with test button

how to reset circuit breaker with test button

high voltage cable testing standards

high voltage cable testing standards