The difference between DC partial discharge test and AC partial discharge test, how to perform partial discharge test?

DC partial discharge test is a test without power. Because "DC" may mean that the current flows in one direction. Then this test is used to detect whether there is micro leakage current in the insulation material, so as to determine whether there is a fault or aging. For example, if there are cracks inside or the material is aged, micro leakage current may occur in equipment such as transformers and cables, and DC testing can be used to detect it.

In terms of steps, you should first disconnect the circuit to ensure that no current flows. Then connect the test equipment and measure the size and distribution of the micro leakage current. If the current is high, it means that there is a problem. Sometimes an oscilloscope or other instrument is used to monitor the changes.

What about the AC partial discharge test? It should be carried out under power, right? Because "AC" usually involves sinusoidal waveform current. This test is also used to detect whether the insulation is good, but what is the difference from the DC test?

In terms of steps, you may need to turn on the power first, and then use the AC test equipment to measure the micro leakage current. In addition, the AC test may be a little more complicated, such as adjusting the phase or frequency and observing the changes.

In terms of differences, it is mainly in the working state: DC is not charged, and AC is charged. The type of equipment tested may also be different? For example, a DC test may be used for a more comprehensive analysis in a disconnected state, while an AC test may detect anomalies during operation.

In addition, the application areas may be different. DC tests may be used for safety inspections of high-voltage equipment, while AC tests may monitor insulation conditions during daily operation. Also, the test methods may be different, such as whether isolation or specific test equipment is required.

In AC testing, if the current is very high, it may affect the measurement accuracy, so a low-value amplifier or other measures are needed to handle it. DC testing is more direct because there is no voltage problem.

In addition, the choice of test equipment is also important. DC testing may use a digital meter or a more accurate detector, while AC testing may require a more sensitive instrument or have a higher frequency adaptability.

Demix Power Test Engineer summarized that DC partial discharge testing is performed with the circuit disconnected and is suitable for checking insulation conditions; while AC partial discharge testing is performed in a live state and is also used to detect insulation performance. Both are important tools to help ensure the safe operation of power equipment.

In AC testing, if the current is very high, it may affect the measurement accuracy, so a low-value amplifier or other measures are needed to deal with it. DC testing is more direct because there is no voltage problem.

In addition, the choice of test equipment is also important. DC testing may use a digital meter or a more accurate detector, while AC testing may require a more sensitive instrument or a higher frequency adaptability.

Demix Power Test Engineer summarized that DC partial discharge testing is performed when the circuit is disconnected and is suitable for checking the insulation status; while AC partial discharge testing is performed when the power is on and is also used to detect insulation performance. Both are important tools to help ensure the safe operation of power equipment.

DC partial discharge testing and AC partial discharge testing are two commonly used insulation detection methods in power systems, each with its own characteristics and applicable scenarios. The following are their definitions, steps and differences:

1. DC partial discharge testing

Definition:

DC partial discharge testing is performed when the circuit is disconnected (no current flows) and is used to detect micro leakage currents in insulating materials. It is suitable for evaluating the insulation performance of equipment such as transformers and cables in a non-powered state.

Steps: Disconnect the circuit: Make sure the device under test is in a completely disconnected state and no current is flowing.

Connect the test equipment: Use an oscilloscope or digital meter to measure the micro leakage current.

Measurement and analysis: Record the size, distribution and changes of the micro leakage current. High current may indicate an insulation problem.

2. AC partial discharge test

Definition: The AC partial discharge test is performed when the device under test is energized, and is also used to detect insulation performance. It is suitable for evaluating the insulation state of the device in operation.

Steps: Turn on the power: Send the device to the energized state.

Connect the test equipment: Use an AC tester to measure the amplitude and phase change of the micro leakage current.

Analysis results: Monitor the current change to determine the insulation condition.

3. Main differences

Working state: DC test is performed in the disconnected state, and AC test is performed in the energized state.

Applicable scenarios: DC test is used for insulation inspection in static or low-frequency conditions, and AC test is suitable for monitoring in dynamic or high-frequency environments.

Equipment requirements: DC testing may require instruments with higher sensitivity, while AC testing needs to adapt to power supplies of different frequencies.

Application areas: DC testing is often used for safety inspections of high-voltage equipment, while AC testing monitors insulation status during daily operation.

Summary

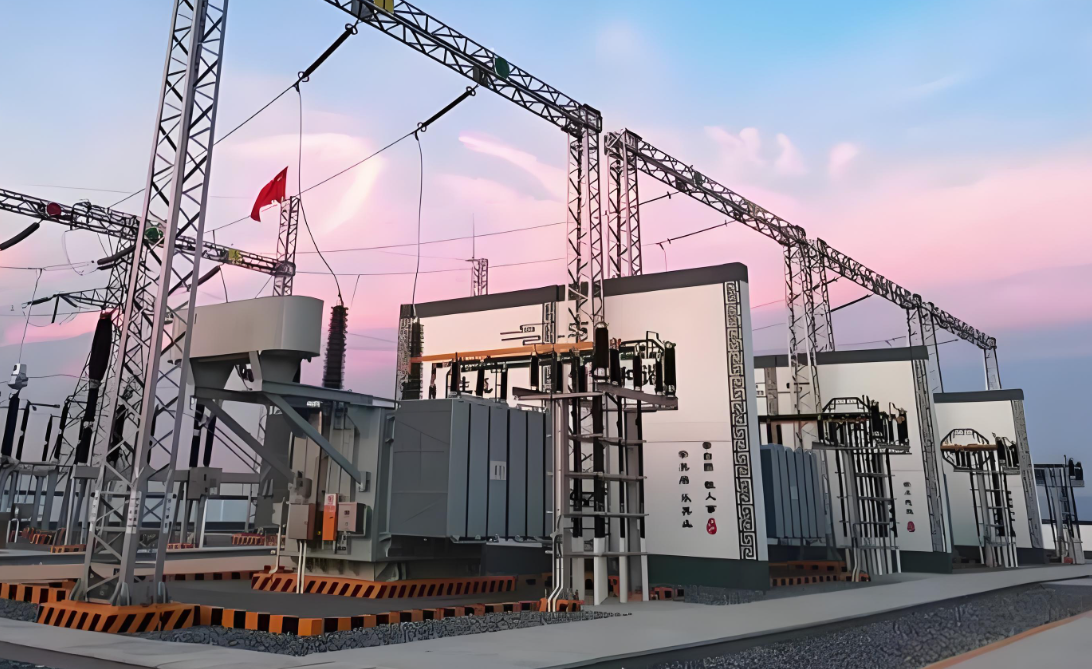

The above content by demiks finishing released, reproduced please specify, demiks is a substation equipment manufacturers, specializing in the production of partial discharge tester, transformer test equipment, circuit breaker test equipment, relay tester, SF6 gas analyser, cable fault tester and other products, such as electric power testing and inspection needs please feel free to contact demiks power science and technology limited company or send an email! to us: contact@demikspower.com

Relay Protection Testing and Commissioning Gu

Relay Protection Testing and Commissioning Gu

how to test microwave transformer

how to test microwave transformer

how to reset circuit breaker with test button

how to reset circuit breaker with test button

high voltage cable testing standards

high voltage cable testing standards