Essential tools for the diagnosis and maintenance of high voltage cable test equipment

Testing high-voltage (HV) cables ensures reliability, safety, and longevity of power transmission and distribution systems. Various specialized equipment is used for installation checks, fault location, and preventive maintenance.

1. Cable Insulation Testing Equipment

A. Megohmmeter (Insulation Resistance Tester)

Purpose: Measures insulation resistance (IR) between conductors and ground.

Voltage Range: 500V to 10kV DC.

Standards: IEEE 43, IEC 60502.

Applications:

Detects moisture, contamination, and insulation degradation.

Acceptance Criteria: Typically > 1 GΩ/km for new cables.

B. Dielectric Absorption Ratio (DAR) & Polarization Index (PI) Test

Equipment: High-voltage Megger (5kV or 10kV).

Purpose: Assesses insulation aging.

DAR = 1-min IR / 30-sec IR (Good if >1.3).

PI = 10-min IR / 1-min IR (Good if >2.0).

C. Tan Delta (Dissipation Factor) Test

Equipment: HV Tan Delta / Power Factor Test Kit.

Purpose: Detects insulation deterioration (voids, moisture).

Acceptance Criteria: Tan δ < 0.5% (new XLPE cables).

2. High Voltage Withstand & Partial Discharge (PD) Testing

A. DC Hi-Pot Test (For MV/HV Cables)

Equipment: DC Hipot Tester (Up to 100kV).

Purpose: Checks insulation integrity under high stress.

Test Voltage: 1.7 to 2 x rated voltage (IEEE 400).

Risk: Can damage XLPE cables (prefer VLF for modern cables).

B. Very Low Frequency (VLF) Test (0.1Hz AC)

Equipment: VLF Hipoter (Up to 50kV).

Purpose: Safer alternative to DC for aged XLPE/PE cables.

Standards: IEEE 400.2, IEC 60502.

C. Partial Discharge (PD) Test

Equipment: PD Detector + Coupling Capacitor.

Purpose: Locates internal defects (voids, cracks).

Methods:

Offline PD Testing (Withstand voltage + PD measurement).

Online PD Monitoring (Ultrasonic/TE sensors).

3. Cable Fault Location Equipment

A. Time Domain Reflectometer (TDR)

Purpose: Finds open circuits, short circuits, and impedance changes.

Range: Up to 50 km (depends on cable type).

B. Surge Generator (Thumper) + Arc Reflection Method

Purpose: Locates high-resistance faults.

Method: Generates a high-voltage surge to create a flashover at the fault.

C. Cable Fault Pre-locator (Impulse Current Method)

Equipment: HV Pulse Generator + Current Detector.

Purpose: Pinpoints exact fault location.

4. Cable Diagnostics & Advanced Testing

A. Frequency Domain Spectroscopy (FDS)

Purpose: Assesses insulation aging (water treeing in XLPE).

B. Tan Delta Mapping (For Long Cables)

Purpose: Identifies weak spots along the cable length.

C. Sheath Integrity Test (For HV Cables with Metallic Sheath)

Equipment: Sheath Test Set (10kV DC).

Purpose: Checks for sheath damage (moisture ingress risk).

5. On-Site Commissioning Tests

Sequence & Phase Verification (Ensures correct phasing).

Continuity & Conductor Resistance Test (Micro-ohmmeter).

Cable Capacitance & Inductance Measurement (LCR Meter).

Selection Guide for HV Cable Testing Equipment

| Test Type | Recommended Equipment | Voltage Range |

|---|---|---|

| Insulation Resistance | Megohmmeter (5kV/10kV) | 500V - 10kV DC |

| VLF Testing | VLF Hipoter (0.1Hz AC) | Up to 50kV |

| Partial Discharge | PD Analyzer + Couplers | 1kV - 35kV |

| Fault Location | TDR + Surge Generator | Up to 150kV |

| Tan Delta | HV Tan Delta Kit | 2kV - 12kV |

Safety Precautions

✔ De-energize & ground cables before testing.

✔ Use proper PPE (gloves, safety barriers).

✔ Follow IEEE/IEC standards for test voltages.

Conclusion

HV cable testing requires a mix of insulation diagnostics, withstand tests, and fault location tools. Regular testing prevents unplanned outages and extends cable life.

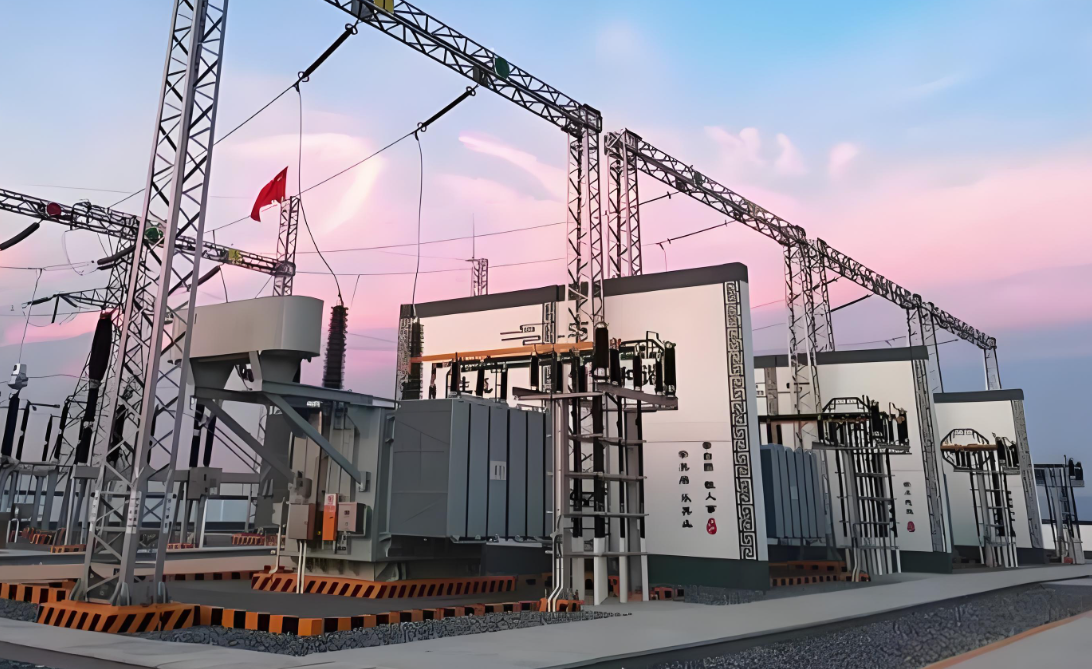

The above content is published by demiks, please specify, demiks is a substation equipment manufacturer, specializing in the production of high-voltage tester, transformer test equipment, circuit breaker test equipment, relay tester, SF6 gas analyser, cable fault tester and other products, if you have power test testing needs, please feel free to contact demiks power science and technology limited company or send an email! Give us: contact@demikspower.com

Relay Protection Testing and Commissioning Gu

Relay Protection Testing and Commissioning Gu

how to test microwave transformer

how to test microwave transformer

how to reset circuit breaker with test button

how to reset circuit breaker with test button

high voltage cable testing standards

high voltage cable testing standards