Guidelines for the Design, Equipment and Maintenance of Lightning Protected Substations

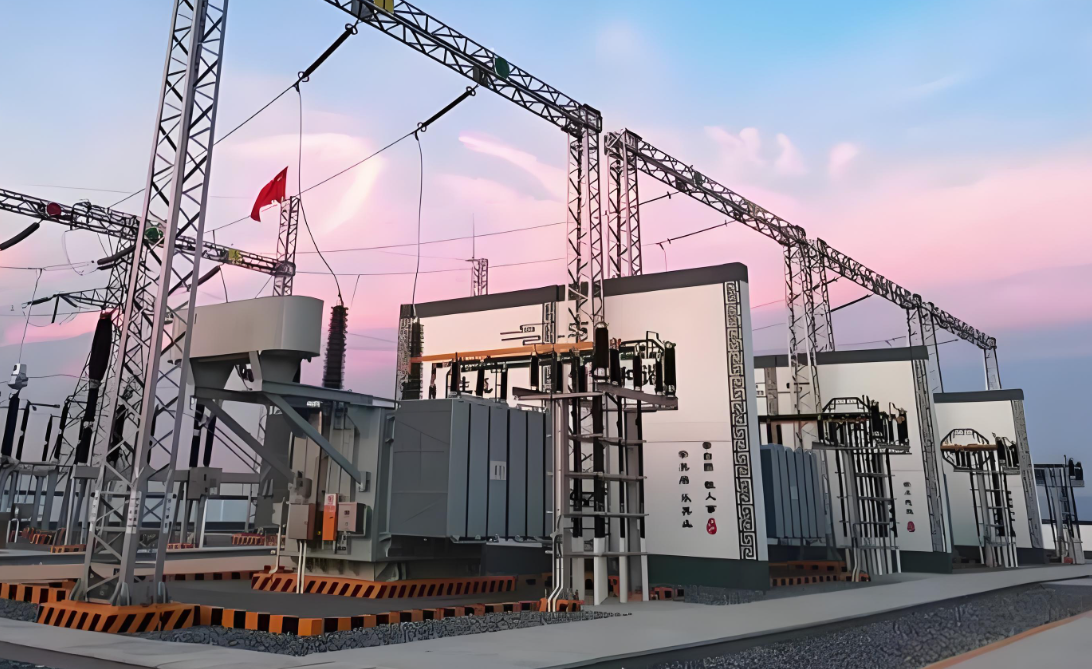

1. Introduction to Substation Lightning Protection

Lightning strikes pose one of the greatest risks to electrical substations, potentially causing:

Damage to substation equipment (transformers, circuit breakers, insulators)

Power outages and grid instability

Fire hazards and safety risks

Effective lightning protection combines external shielding (against direct strikes) and internal protection (against surges).

2. Key Components of Substation Lightning Protection

A. External Protection (Direct Strike Mitigation)

| Component | Function | Design Considerations |

|---|---|---|

| Lightning masts | Intercept direct strikes | Height calculated via rolling sphere method (typically 30-45m for 110kV substations) |

| Overhead shield wires | Protect incoming transmission lines | Installed 2-4km from substation; angle ≤30° |

| Mesh shielding (Faraday cage) | Enclose substation in conductive mesh | Mesh size ≤5m×5m for high-risk areas |

B. Internal Protection (Surge Suppression)

| Device | Application | Key Specs |

|---|---|---|

| Surge arresters (MOA) | Limit overvoltage at equipment | Voltage rating: 10-500kV; residual voltage ratio <2.5 |

| SPDs (Surge Protective Devices) | Protect control systems | Class I (100kA), II (40kA), III (20kA) |

| Isolation transformers | Prevent surge propagation | Shielded windings, 1:1 ratio |

3. Grounding System Design

A low-impedance ground network is critical for dissipating lightning current safely:

Target ground resistance: ≤5Ω (≤0.5Ω for critical EHV substations)

Materials: Copper-clad steel rods (≥3m deep) or chemical electrodes

Grid configuration:

Mesh size ≤10m×10m

Equipotential bonding for all metallic structures

Lightning mast grounding: Separate electrode (≥3m from main grid) to prevent "backflash"

4. Lightning Risk Assessment & Standards

A. Risk Calculation (IEC 62305)

Risk (R) = (Probability of strike) × (Consequences)

Factors: Local keraunic level (thunderstorm days/year), soil resistivity, equipment BIL (Basic Insulation Level)

B. International Standards

| Standard | Scope |

|---|---|

| IEC 62305 | Lightning protection system design |

| IEEE 998 | Substation shielding guidelines |

| NFPA 780 | Lightning protection installation |

| GB 50057-2010 | Chinese lightning protection code |

5. Maintenance & Testing

Annual inspections:

Check arrester leakage current (should be <1mA)

Measure ground resistance (spring/fall)

Inspect SPD status indicators

After severe storms:

Thermographic scan of connections

Insulation resistance tests

6. Case Study: 220kV Substation Protection

Problem: Frequent lightning-caused outages in mountainous region.

Solution:

Installed 4×45m lightning masts (rolling sphere radius=45m)

Upgraded to ZnO surge arresters (Uc=192kV, residual <400kV)

Improved grounding with 2,000m copper grid + 20 deep electrodes (R=0.8Ω)

Result: Zero lightning-related failures in 3 years.

7. Emerging Technologies

Early Streamer Emission (ESE) air terminals - 30% larger protection radius

Real-time monitoring:

Arrester leakage current sensors

Lightning current measurement (Rogowski coils)

GIS-based risk mapping for optimal mast placement

8. Cost-Benefit Analysis

| Protection Level | Approx. Cost | Outage Reduction |

|---|---|---|

| Basic (masts + arresters) | $50,000 | 70% |

| Advanced (+SPD + mesh) | $150,000 | 95% |

| Premium (+monitoring) | $300,000 | 99% |

Conclusion

An effective substation lightning protection system requires:

Physical interception of strikes (masts/wires)

Proper grounding to dissipate energy

Surge suppression at all voltage levels

Regular maintenance to ensure integrity

For a customized design, provide:

Substation voltage level (e.g., 110kV, 500kV)

Local lightning density (thunderstorm days/year)

Single-line diagram of existing equipment

The above content is published by demiks, please specify, demiks is a substation equipment manufacturer, specializing in the production of high-voltage tester, transformer test equipment, circuit breaker test equipment, relay tester, SF6 gas analyser, cable fault tester and other products, if you have power test testing needs, please feel free to contact demiks power science and technology limited company or send an email! Give us: contact@demikspower.com

Relay Protection Testing and Commissioning Gu

Relay Protection Testing and Commissioning Gu

how to test microwave transformer

how to test microwave transformer

how to reset circuit breaker with test button

how to reset circuit breaker with test button

high voltage cable testing standards

high voltage cable testing standards