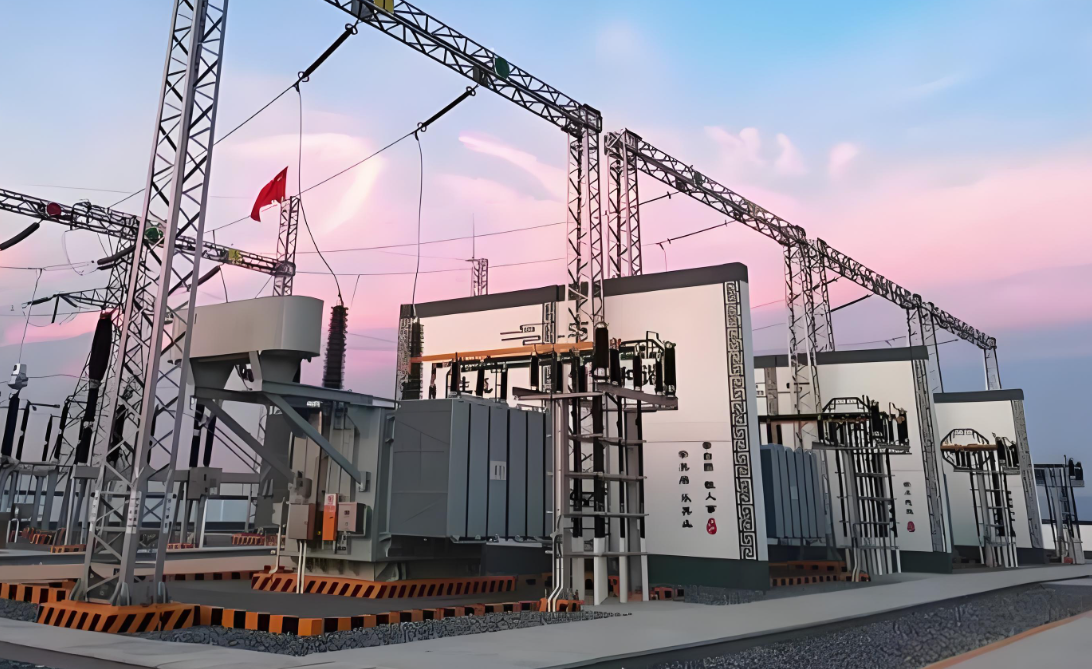

design guide for rural substations

Senior technical engineers at substation equipment manufacturers speak of the need for careful planning in designing rural substations to ensure reliability, safety, and cost-effectiveness, while taking into account the unique challenges of rural areas (e.g., limited infrastructure, harsh environments, and low power demand). The following are structured design guidelines for rural substations:

1. Key Considerations for Rural Substation Design

A. Site Selection

Accessibility: Ensure the site is reachable for maintenance, even in bad weather.

Topography: Flat, elevated land to avoid flooding.

Proximity to Load Centers: Minimize transmission losses by locating near demand areas.

Environmental Impact: Avoid ecologically sensitive zones.

B. Electrical Requirements

Voltage Levels: Typically 11kV/33kV to 400V (depends on local grid).

Load Capacity: Rural loads are usually smaller; size transformers accordingly.

Redundancy: Consider single vs. double transformer setups (cost vs. reliability).

C. Safety & Protection

Lightning Protection: Install surge arresters and grounding systems.

Fire Safety: Fire-resistant materials, oil containment for transformers.

Fencing & Security: Prevent unauthorized access (animals, vandalism).

2. Rural Substation Layout & Components

A. Compact Design (Common for Rural Areas)

Pole-Mounted Substations (for very small loads):

Transformers mounted on poles.

Minimal land use, low cost.

Package (Prefabricated) Substations:

Pre-assembled, easy to install.

Includes switchgear, transformers, and protection in one unit.

Conventional Outdoor Substations (for larger loads):

Fenced area with separate components (transformers, breakers, etc.).

B. Main Components

| Component | Purpose |

|---|---|

| Step-down Transformer | Reduces HV (11kV/33kV) to LV (400V). |

| Circuit Breakers | Protects against overloads/short circuits. |

| Isolators | Allows safe maintenance. |

| Surge Arresters | Protects against lightning/voltage spikes. |

| Metering & Protection Relays | Monitors power flow and trips in faults. |

| Control Panel | Houses protection and monitoring devices. |

| Earthing System | Ensures safety by grounding fault currents. |

3. Design Standards & Compliance

IEEE 80: Grounding safety.

IEC 62271: Switchgear standards.

Local Utility Regulations: Follow national grid codes.

Environmental Clearances: Ensure minimal ecological disruption.

4. Cost Optimization for Rural Substations

Use of Used/Refurbished Equipment (if reliable).

Minimal Civil Works: Prefabricated structures reduce costs.

Modular Design: Allows future expansion.

Solar Hybrid Option: In remote areas, solar + battery can reduce grid dependence.

5. Maintenance & Sustainability

Remote Monitoring: IoT sensors for fault detection.

Durable Materials: Corrosion-resistant, weatherproof equipment.

Training for Local Technicians: Ensures quick repairs.

Conclusion

Rural substations should prioritize simplicity, reliability, and cost-efficiency. The choice between pole-mounted, package, or conventional substations depends on load size and budget. Always comply with safety standards and consider future expansion needs.

The above content is published by demiks, please specify, demiks is a substation equipment manufacturer, specializing in the production of high-voltage tester, transformer tester, circuit breaker test equipment, relay tester, SF6 gas analyser, cable fault tester and other products, if you have power test testing needs, please feel free to contact demiks power science and technology limited company or send an email! Give us: contact@demikspower.com

Relay Protection Testing and Commissioning Gu

Relay Protection Testing and Commissioning Gu

how to test microwave transformer

how to test microwave transformer

how to reset circuit breaker with test button

how to reset circuit breaker with test button

high voltage cable testing standards

high voltage cable testing standards