What are the high voltage cable testing methods

High voltage (HV) cable testing is essential to ensure the reliability, safety and longevity of the transmission and distribution system, as noted by demiks technicians, suppliers of HV testers. Different tests are performed at different stages of factory acceptance, installation, commissioning and maintenance. Below are the main test methods categorised by purpose:

1. Factory Acceptance Tests (FAT)

Conducted by manufacturers before delivery.

A. Routine Tests

Insulation Resistance Test (Megger Test)

Purpose: Checks insulation integrity.

Method: Apply 500V–10kV DC, measure resistance (typically >1 GΩ/km for new cables).

Standard: IEC 60502, IEEE 400.

Partial Discharge (PD) Test

Purpose: Detects voids or defects in insulation.

Method: Apply AC voltage (1.5–2× rated voltage) and measure PD levels (<10 pC for XLPE).

Standard: IEC 60885-3.

High Voltage (AC/DC) Withstand Test

AC Test: 2.5× rated voltage for 30 mins (IEC 60502).

DC Test: 3–4× rated voltage for 15 mins (avoid for XLPE due to space charge risks).

Tan Delta (Dissipation Factor) Test

Purpose: Measures insulation aging/moisture.

Acceptance: Tan δ < 0.5% for new XLPE cables (IEC 60840).

2. On-Site Installation & Commissioning Tests

Performed after cable installation but before energization.

A. Insulation & Continuity Tests

DC Hi-Pot Test

Purpose: Verifies insulation strength.

Voltage: 1.7–2× rated voltage (IEEE 400).

Risk: Not recommended for XLPE (use VLF instead).

Very Low Frequency (VLF) Test (0.1 Hz AC)

Purpose: Safer alternative to DC for aged cables.

Voltage: 1.5–3× rated voltage for 15–60 mins.

Standard: IEEE 400.2.

Time Domain Reflectometry (TDR)

Purpose: Locates open circuits, shorts, or impedance mismatches.

B. Phasing & Polarity Test

Ensures correct phase sequence (R-Y-B) and grounding.

3. Maintenance & Diagnostic Tests

Periodic tests to detect aging or incipient faults.

A. Partial Discharge (PD) Monitoring

Online PD: Uses high-frequency sensors (HFCT/TE).

Offline PD: Requires VLF or AC test sets.

B. Tan Delta Mapping

Identifies localized insulation degradation along the cable length.

C. Dissolved Gas Analysis (DGA) (For Oil-Filled Cables)

Detects internal faults (e.g., arcing, overheating).

D. Frequency Domain Spectroscopy (FDS)

Assesses water treeing in XLPE cables.

4. Fault Location Methods

Used when a cable fails.

A. Surge (Thumper) Method

Generates high-voltage pulses to create audible faults.

B. Arc Reflection Method (ARM)

Combines TDR with surge pulses for high-resistance faults.

C. Voltage Decay Method

Measures discharge rate to locate insulation weaknesses.

5. Standards & Safety

International Standards: IEC 60502, IEEE 400, CIGRE TB 303.

Safety: Always de-energize, ground, and use PPE (gloves, goggles).

Summary Table: HV Cable Testing Methods

| Test Type | Purpose | Equipment | Applicable Stage |

|---|---|---|---|

| Insulation Resistance | Checks insulation health | Megohmmeter (5kV/10kV) | Factory, Installation |

| VLF Testing | Safe AC withstand for aged cables | VLF Hipoter (0.1Hz) | Commissioning, Maintenance |

| Partial Discharge | Detects voids/cracks | PD Analyzer + Couplers | Factory, Maintenance |

| Tan Delta | Measures insulation loss | HV Tan Delta Kit | Factory, Diagnostic |

| TDR | Locates breaks/shorts | Time Domain Reflectometer | Installation, Fault Finding |

Key Takeaways

For New Cables: Focus on factory tests (PD, Tan Delta, AC withstand).

For Aged Cables: Use VLF + Tan Delta + PD monitoring.

Fault Location: TDR + Surge generator for precise results.

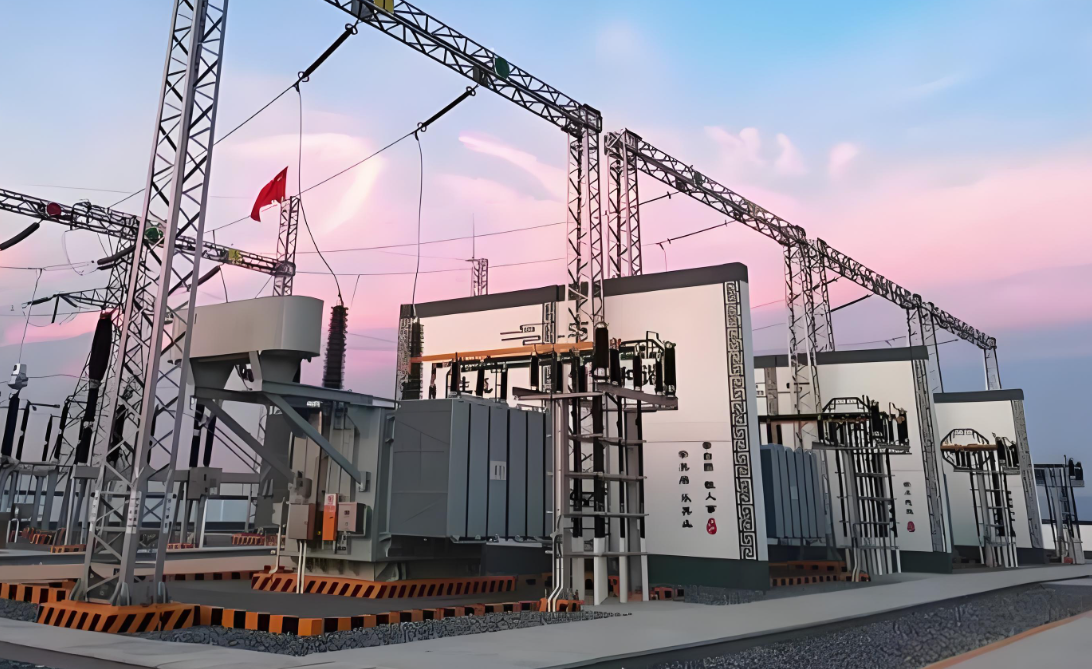

The above content is published by demiks, please specify, demiks is a substation equipment manufacturer, specializing in the production of high-voltage tester, transformer test equipment, circuit breaker test equipment, relay tester, SF6 gas analyser, cable fault tester and other products, if you have power test testing needs, please feel free to contact demiks power science and technology limited company or send an email! Give us: contact@demikspower.com

Relay Protection Testing and Commissioning Gu

Relay Protection Testing and Commissioning Gu

how to test microwave transformer

how to test microwave transformer

how to reset circuit breaker with test button

how to reset circuit breaker with test button

high voltage cable testing standards

high voltage cable testing standards