Detailed explanation of the difference between the grading ring and the grading ball in the high-voltage bushing and their respective functions

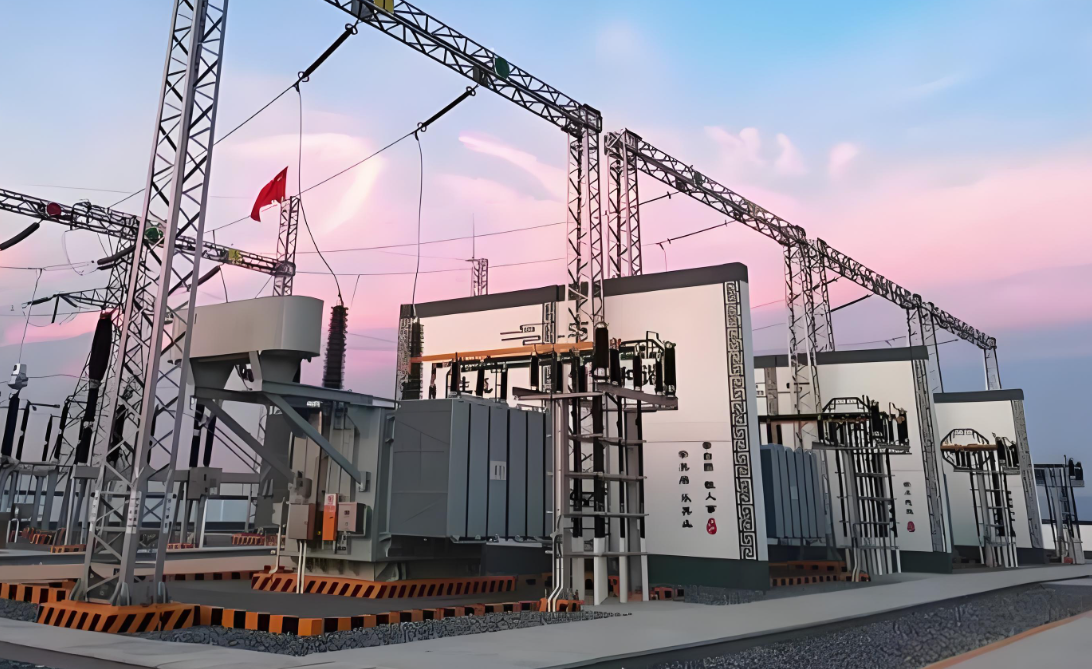

As a key equipment in the AC transmission and transformation system of the power industry, the oil-paper capacitor transformer bears the heavy responsibility of transmitting electric energy. In the medium voltage level range of 60-110kV, this type of transformer plays a vital role. Its basic structure is oil-immersed, that is, the winding and core of the transformer are sealed in an iron oil tank, and the transformer insulating oil is injected into the tank. The connection between the transformer body and the external transmission and transformation line depends on the oil-paper capacitor transformer bushing installed on the box cover. This bushing not only carries the task of transmitting current, but also is a key component to ensure the safe operation of the system.

Bushing, as a current-carrying outlet device, must have the specified electrical strength and sufficient mechanical strength. Its upper part is in contact with the external air or cable outlet device, the middle part is firmly mounted on the measuring device or the box cover flange, and the lower part is immersed in the internal oil of the oil tank. It is worth noting that a certain insulation distance must be maintained between the live part of the lower bushing and the grounded part, such as the tank wall, flange, and core clamp. This distance is set according to the test voltage of the transformer and increases with the increase of the voltage level. In addition, the size of the insulation distance is also closely related to the structure of the live part of the bushing and the shape of the grounded part. Especially for voltage levels above 60kV, the lower end of the bushing is usually equipped with a grading ball with rounded edges, while the shape of the grounded part may include various forms such as sharp corners, arcs or planes.

The grading ring on the upper part of the transformer bushing is usually installed on the top of the insulator bushing and is in the form of an annular steel ring. What is the key role of this device?

Since the voltage distribution of an insulator is often uneven when it is struck by lightning, most of the voltage drop is concentrated in a very short distance near the end struck by lightning. This means that the insulation strength of this area must be very high, otherwise once a local breakdown occurs, this uneven voltage distribution will further affect the next section of the insulator. The situation will become more serious as the breakdown length of the insulator increases. However, increasing the insulation strength will lead to a significant increase in the cost. To solve this problem, a voltage grading ring can be installed on the head of the insulator (i.e. the part struck by lightning). The voltage grading ring uses its inductance effect to balance the capacitive current to the ground, so that the lightning overvoltage can be distributed relatively evenly. In this way, the full length of the insulator can be more fully utilized to resist the impact of lightning, thereby improving the electric field distribution and avoiding excessive field strength in individual parts or points.

How to optimize the voltage-equalizing ball at the bottom of the transformer bushing and the synergistic effect of the riser?

As the cornerstone of the power grid, the transformer bushing plays a vital role as a bridge connecting power and the transformer. In every link of power transmission, the stability of the bushing directly affects the safety of the transformer and even the entire power grid. In a high-voltage environment, insulation failure of the transformer becomes the most common hidden danger, so it is particularly urgent to deeply analyze the insulation problem inside the bushing. At present, the research on bushing insulation focuses on its own voltage resistance, but rarely combines it with the transformer itself. However, the bushing is ultimately to be installed on the transformer, and its actual operating environment is very different from that when tested alone. Therefore, it is necessary to combine the bushing with the riser of the transformer to jointly explore the electric field distribution inside the bushing, aiming to improve the reliability of its insulation and realize the lightweight design of the riser.

Based on the breakdown theory of transformer oil, some literature has deeply explored the electric field distribution characteristics around the voltage-equalizing ball at the tail of the bushing. This study not only introduces the key theory in transformer insulation design, the oil volume theory, in detail, but also proposes a calculation method for the allowable field strength in the transformer internal insulation design. Taking the high-voltage bushing grading ball and the riser seat of the State Grid 220kV transformer as the research object, this paper uses two electric field simulation technologies, namely the surface charge method and the finite element method, to conduct a detailed analysis. On the basis of accurately calculating the surface field strength of the grading ball, the paper focuses on the factors affecting the field strength, especially the fillet of the grading ball and the thickness of the surface insulation cover. At the same time, combined with the actual manufacturing feasibility, an optimization scheme for the fillet and insulation cover thickness is proposed. In addition, this study also explores the miniaturization design of the riser seat diameter. The finite element method is used to calculate in detail the change of the electric field on the surface of the grading ball after the diameter of the riser seat is reduced, and the allowable field strength is determined in combination with the oil volume theory to ensure sufficient safety margin. Finally, the optimization scheme is applied to the actual 220kV transformer bushing, and insulation tests are carried out separately and fully assembled in the transformer, all of which are successful, thus verifying the effectiveness of the optimization scheme. This solution starts with the chamfering of the voltage-equalizing ball and the surface insulation coating, which effectively reduces the diameter of the riser seat, not only saving manufacturing costs, but also providing a useful reference and guidance for the selection of the size of the corresponding voltage level bushing riser seat in the future. For high-voltage power insulation testing, high-voltage voltage-equalizing rings, and insulation withstand voltage testing, please contact Demiks Power Technology Co., Ltd. Contact email: contact@demikspower.com

Relay Protection Testing and Commissioning Gu

Relay Protection Testing and Commissioning Gu

how to test microwave transformer

how to test microwave transformer

how to reset circuit breaker with test button

how to reset circuit breaker with test button

high voltage cable testing standards

high voltage cable testing standards