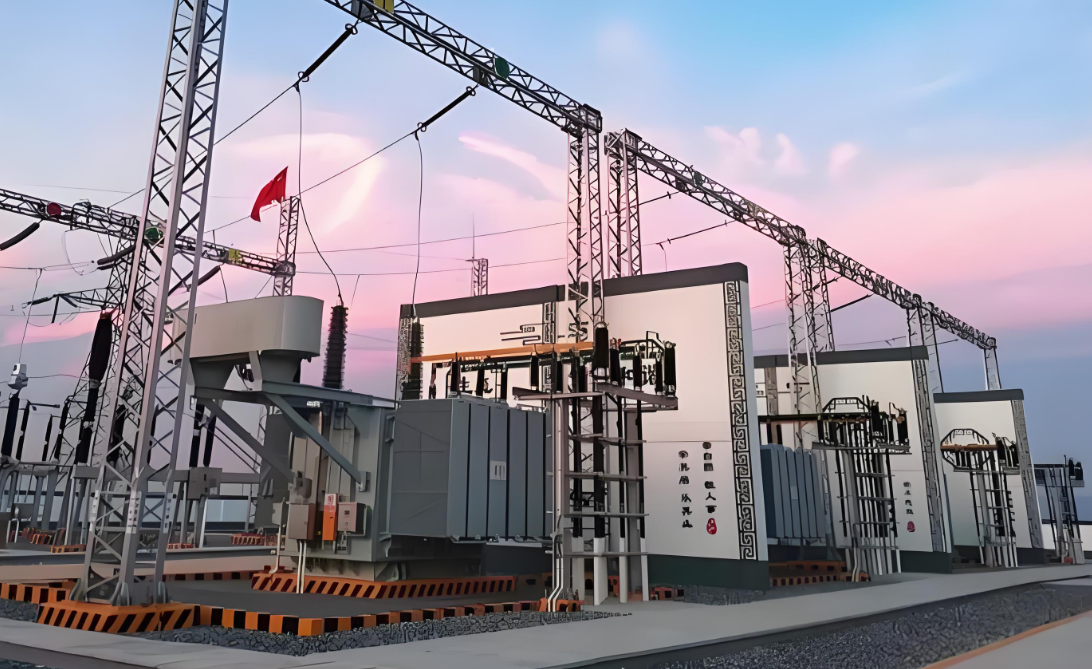

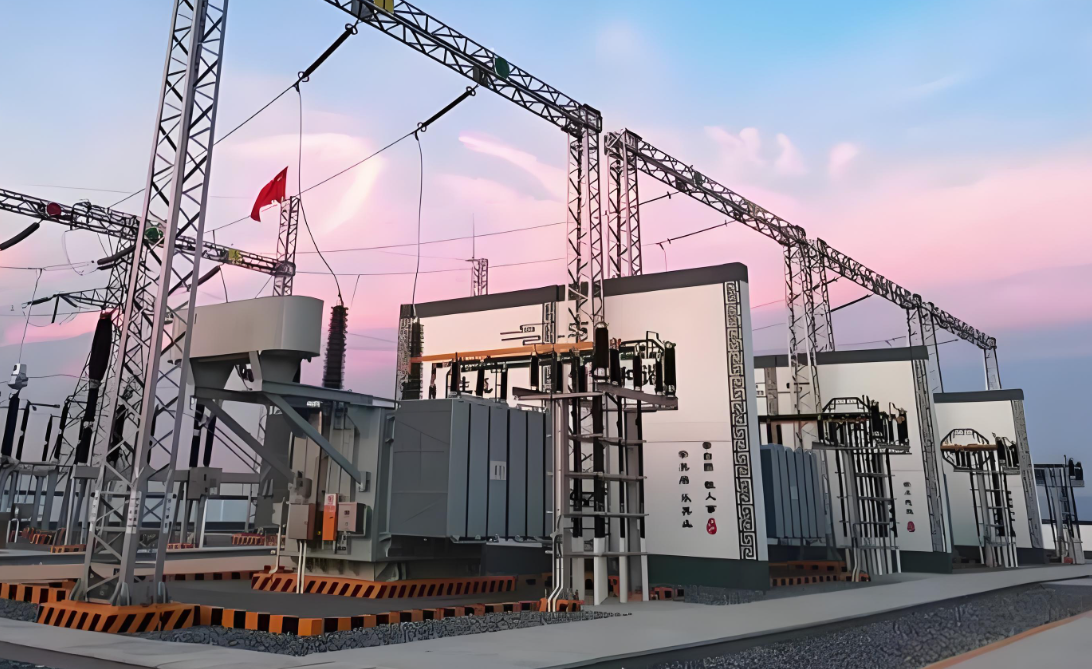

Substation Electrical Maintenance and Frequently Asked Questions

Substation Equipment Maintenance: Best Practices and Procedures

Proper maintenance of substations is critical to ensuring the reliability, safety and longevity of equipment. Regular inspections, testing and repairs help prevent failures, reduce downtime and improve grid performance.

1. Types of Substation Maintenance

A. Preventive Maintenance (PM)

Scheduled inspections & servicing to prevent failures.

Includes cleaning, lubrication, tightening connections, and testing.

B. Predictive Maintenance (PdM)

Uses condition monitoring (thermography, oil testing, partial discharge tests).

Detects early signs of wear before failure occurs.

C. Corrective Maintenance (CM)

Repairs after a fault occurs (e.g., replacing a failed circuit breaker).

D. Reliability-Centered Maintenance (RCM)

Focuses on critical components to optimize maintenance efforts.

2. Key Maintenance Activities

A. Transformer Maintenance

Oil Testing (Dielectric strength, moisture, dissolved gas analysis - DGA).

Winding Resistance Test (Checks for loose connections).

Bushing & Tap Changer Inspection (Mechanical wear, overheating).

Thermal Imaging (Hotspots due to poor connections).

B. Circuit Breaker Maintenance

Contact Resistance Measurement (Ensures low resistance).

Insulation Resistance Test (Checks for degradation).

Mechanical Operation Test (Ensures smooth opening/closing).

SF6 Gas Pressure Check (For gas-insulated breakers).

C. Switchgear & Busbar Maintenance

Tightness Check (Loose bolts cause overheating).

Partial Discharge Detection (Early insulation failure signs).

Visual Inspection (Corrosion, dust, moisture).

D. Protection Relay & Metering Maintenance

Calibration (Ensures accurate tripping).

Functional Testing (Simulates faults to verify response).

Firmware Updates (For digital relays).

E. Grounding & Lightning Protection

Earth Resistance Test (Should be <5Ω for safety).

Lightning Arrester Check (Damage, leakage current).

F. Battery & DC System Maintenance

Voltage & Specific Gravity Test (For backup batteries).

Load Testing (Ensures UPS can support critical loads).

3. Maintenance Schedule

| Equipment | Maintenance Frequency |

|---|---|

| Transformers | Annual (Oil testing every 6 months) |

| Circuit Breakers | Every 1-2 years (or after 2000 operations) |

| Switchgear & Busbars | Biannual (Thermal scan yearly) |

| Protection Relays | Annual (Functional test every 2 years) |

| Grounding System | Every 3 years (or after major storms) |

| Batteries (UPS) | Quarterly (Monthly visual checks) |

4. Safety Precautions During Maintenance

✔ De-energize equipment (Lockout-Tagout - LOTO).

✔ Use proper PPE (Insulated gloves, arc-flash suits).

✔ Follow IEEE & NFPA 70E safety standards.

✔ Discharge capacitors before working.

✔ Ventilate when dealing with SF6 gas or oil.

5. Common Substation Problems & Solutions

| Issue | Solution |

|---|---|

| Overheating connections | Tighten bolts, apply contact grease |

| Oil leakage in transformer | Replace gaskets, monitor oil levels |

| Relay misoperation | Recalibrate, check wiring |

| Corrosion in busbars | Clean, apply anti-corrosion coating |

| High earth resistance | Improve grounding with bentonite |

Conclusion

Effective substation maintenance requires planning, testing, and adherence to safety standards. A well-maintained substation ensures:

✅ Reduced downtime

✅ Extended equipment life

✅ Improved safety

✅ Cost savings (Prevents major breakdowns)

The above content is published by demiks, please specify, demiks is a substation equipment manufacturer, specializing in the production of high-voltage tester, transformer test equipment, circuit breaker test equipment, relay tester, SF6 gas analyser, cable fault tester and other products, if you have power test testing needs, please feel free to contact demiks power science and technology limited company or send an email! Give us: contact@demikspower.com

Relay Protection Testing and Commissioning Gu

Relay Protection Testing and Commissioning Gu

how to test microwave transformer

how to test microwave transformer

how to reset circuit breaker with test button

how to reset circuit breaker with test button

high voltage cable testing standards

high voltage cable testing standards