Partial Discharge Test Equipment Uses and Features

Partial Discharge test equipment is used to detect, measure, and analyze partial discharges in high-voltage electrical equipment. These devices are essential for assessing the insulation condition of equipment such as transformers, cables, switchgear, and rotating machines. Below is an overview of the key types of partial discharge test equipment, their functions, and applications:

1. Partial Discharge Detector/Analyzer

Function:

Measures the magnitude, frequency, and phase of partial discharges.

Provides real-time PD waveforms and statistical analysis.

Features:

High sensitivity to detect weak PD signals.

Multi-channel capability for complex systems.

Complies with international standards (e.g., IEC 60270).

Applications:

PD testing in transformers, cables, switchgear, and other high-voltage equipment.

2. High-Frequency Current Transformer (HFCT)

Function:

Detects PD signals by measuring high-frequency currents in the ground lead of equipment.

Features:

Non-intrusive and easy to install.

Suitable for online monitoring.

Applications:

PD detection in cables and transformers.

Ground wire PD monitoring.

3. Transient Earth Voltage (TEV) Sensor

Function:

Detects transient earth voltages generated by PD activity.

Features:

Ideal for metal-enclosed equipment like switchgear.

Portable and suitable for field testing.

Applications:

PD detection in switchgear, ring main units, and other enclosed systems.

4. Ultrasonic Sensor

Function:

Detects ultrasonic emissions caused by PD activity.

Features:

Immune to electromagnetic interference.

Effective for surface discharges and corona.

Applications:

PD detection in transformers, switchgear, and cable terminations.

5. Ultraviolet (UV) Camera

Function:

Captures UV light emitted by corona discharges.

Features:

Visualizes PD activity in real-time.

Suitable for outdoor inspections.

Applications:

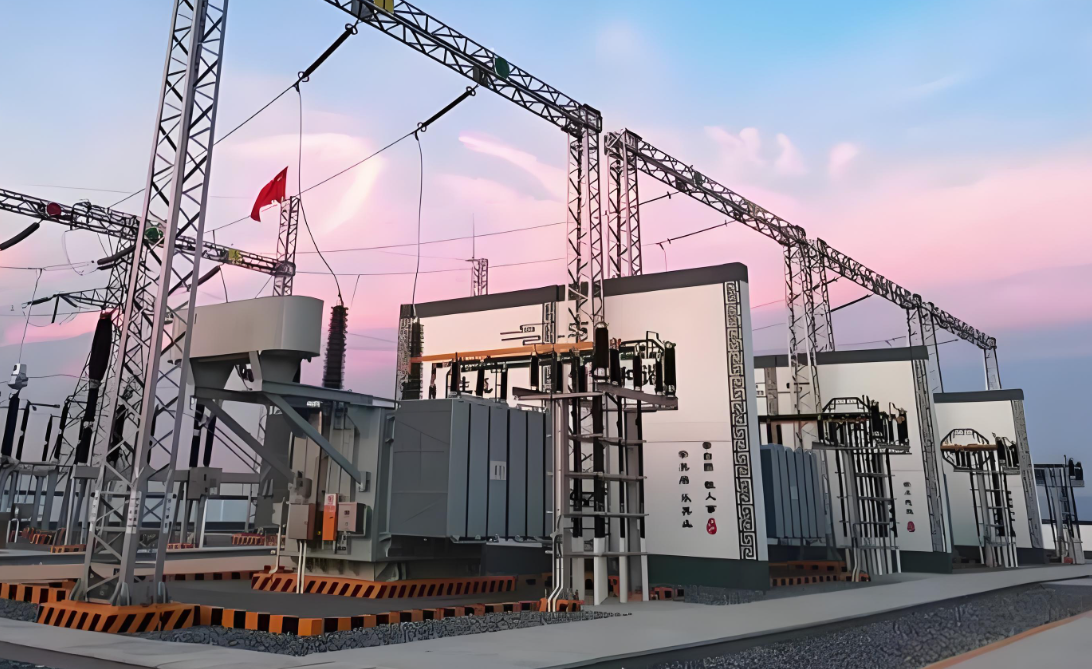

Corona detection in transmission lines, substations, and outdoor equipment.

6. Coupling Capacitor

Function:

Couples PD signals from the test object to the measuring instrument.

Features:

High-voltage withstand capability.

Used in conjunction with PD detectors.

Applications:

PD testing in transformers, cables, and other high-voltage equipment.

7. PD Calibrator

Function:

Calibrates PD measurement systems by injecting known PD pulses.

Features:

Ensures accurate and reliable PD measurements.

Portable and easy to use.

Applications:

Calibration of PD test equipment before measurements.

8. Online PD Monitoring System

Function:

Continuously monitors PD activity in real-time.

Features:

Provides trend analysis and early warning of insulation degradation.

Supports remote data transmission and alarms.

Applications:

Long-term PD monitoring in transformers, cables, and switchgear.

9. Phase-Resolved Partial Discharge (PRPD) Analyzer

Function:

Analyzes PD patterns over the voltage cycle (phase-resolved analysis).

Features:

Distinguishes between different types of PD (e.g., internal, surface, corona).

Provides detailed statistical data and discharge patterns.

Applications:

Advanced PD diagnostics and fault localization.

10. Gas Chromatograph (for Dissolved Gas Analysis, DGA)

Function:

Detects gases produced by PD activity in oil-filled equipment.

Features:

Identifies specific gases (e.g., H₂, CH₄, C₂H₂) to assess PD severity.

Applications:

PD detection in oil-immersed transformers and reactors.

Key Considerations for Selecting PD Test Equipment

Type of Equipment: Choose equipment suitable for the device under test (e.g., transformer, cable, switchgear).

Sensitivity: Ensure the device can detect low-level PD signals.

Portability: For field testing, portable devices are preferred.

Compliance: Verify that the equipment meets relevant standards (e.g., IEC 60270).

Data Analysis: Look for advanced analysis features (e.g., PRPD, trend analysis).

Environmental Conditions: Consider factors like electromagnetic interference, temperature, and humidity.

Applications of PD Test Equipment

Transformers: Detect insulation defects, moisture, and aging.

Cables: Identify voids, water trees, and other insulation issues.

Switchgear: Assess insulation and connection integrity.

Rotating Machines: Detect stator winding insulation problems.

Transmission Lines: Monitor corona and surface discharges.

Benefits of PD Testing

Early Detection: Identifies insulation issues before they cause failures.

Preventive Maintenance: Reduces unplanned outages and extends equipment life.

Cost Savings: Minimizes repair costs and improves system reliability.

Challenges in PD Testing

Complexity: Requires specialized knowledge and expertise.

Interference: External noise can affect measurement accuracy.

Interpretation: Skilled analysis is needed to differentiate between harmless and harmful discharges.

Standards for PD Testing

IEC 60270: Standard for partial discharge measurements.

IEEE C57.113: Guide for PD measurement in liquid-immersed transformers.

ASTM D1868: Standard for PD detection and measurement.

Partial discharge test equipment is a critical tool for maintaining the reliability and safety of high-voltage electrical systems. By detecting and analyzing PD activity, these devices help prevent equipment failures and ensure efficient operation.、

Relay Protection Testing and Commissioning Gu

Relay Protection Testing and Commissioning Gu

how to test microwave transformer

how to test microwave transformer

how to reset circuit breaker with test button

how to reset circuit breaker with test button

high voltage cable testing standards

high voltage cable testing standards